News | Wuchuan China Europe Fluorine Electronics 20000 ton Electronic Hydrofluoric Acid Project is about to be put into operation

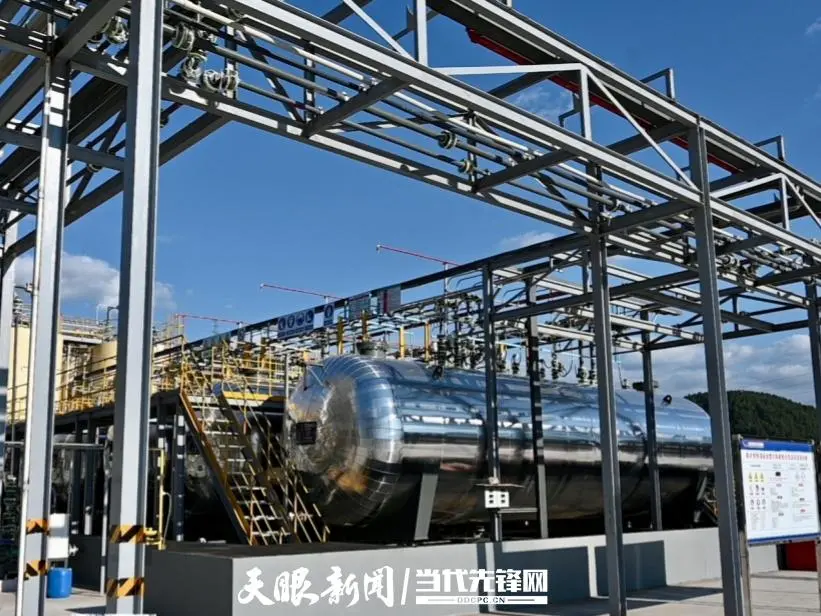

The first phase of the project with an annual output of 20000 tons of electronic grade hydrofluoric acid equipment has been debugged and the enterprise's trial production plan has been approved by relevant departments before it can be put into trial production. In the future, the second phase project with an annual output of 20000 tons of electronic grade hydrofluoric acid can be quickly started with just one more set of equipment, "said Xu Peng, the director of Wuchuan ZhongEurope Fluoroelectronic New Materials Co., Ltd. (ZhongEurope Fluoroelectronic New Materials Co., Ltd.) on June 12th.

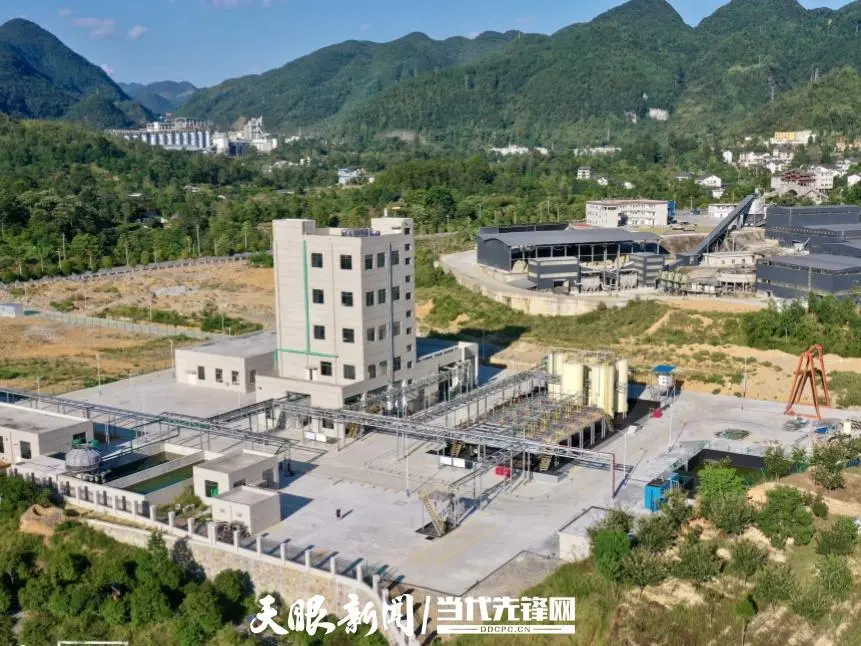

Different from the "phosphorus fluorine" route of developing fluorine chemical industry by utilizing the accompanying fluorine resources of phosphate ore, Wuchuan will rely on abundant fluorite resources, supported by the fluorine barium new material industrial park, and mainly focus on the "fluorescent fluorine" route, to layout and construct a fluorine chemical industry cluster area that follows the obligation of righteousness.

Xu Peng introduced that in industries such as semiconductors and photovoltaics, electronic grade hydrofluoric acid is mainly used for cleaning and etching silicon wafers and chips. Wuxi Dongfeng New Energy Company has been deeply involved in this field for more than ten years, and has traveled thousands of miles to Wuchuan to lay out the fluorine electronics industry, with a focus on the local raw material guarantee.

At present, there are three fluorite and barite co associated ore beneficiation plants in Wuchuan County, with an annual production capacity of 560000 tons. Next, with the support of the local government, China Europe Fluorine Electronic New Materials Company will obtain the right to freely mine fluorite and build a beneficiation plant with an annual output of 300000 tons to enhance the local beneficiation capacity.

Not long ago, China Europe Fluoro Electronic New Materials Company officially signed an agreement with the park to acquire more than 80 acres of industrial construction sites near the existing factory area for the construction of a 60000 ton per year anhydrous hydrogen fluoride project. Among them, the first phase project with an annual output of 30000 tons is expected to be put into operation by the end of next year.

With the establishment of mineral processing plants and the production capacity of anhydrous hydrogen fluoride, the raw materials for electronic grade hydrofluoric acid in enterprises will no longer be purchased externally. Through advanced mineral processing technology, local associated minerals can be processed into fluorite powder with a calcium fluoride content of over 97%, which can be used to produce high-purity anhydrous hydrogen fluoride and further converted into various value-added fluorinated electronic materials.

Previously, the "Guiding Catalogue for Industrial Structure Adjustment (2024 Edition)" issued by the National Development and Reform Commission clearly stated that hydrogen fluoride belongs to restricted industries. Only enterprises that use the produced hydrogen fluoride for downstream deep processing products for self use, electronic grade and wet process phosphoric acid matching, can increase production capacity.

The new production capacity of anhydrous hydrogen fluoride must be converted downstream of the enterprise. Therefore, in order to reduce the external procurement cost of raw materials required for downstream products, Wuchuan Fluorite Resources is expected to achieve "precision opening" at China Europe Fluorine Electronic New Materials Company. China Europe Fluoro Electronic New Materials Company prioritizes the layout of terminal products, which also sends a "reassurance pill" to the park that the enterprise intends to develop in the long term.

With the continuous improvement of industrial supporting facilities, we plan to connect the fluorine electronic new material industry chain in Wuchuan in the next three to four years, which integrates mining, mineral processing, fluorine chemical raw materials, fluorine electronic materials, electronic grade hydrogen peroxide, electronic grade alkali and other auxiliary materials production.