What is the edge voltage of a lithium battery? How to control the edge voltage?

The edge voltage of lithium batteries specifically refers to the voltage of the aluminum layer between the positive electrode ear of the soft pack battery and the aluminum-plastic film.

The edge voltage of soft pack lithium batteries refers to:

1. The voltage of the aluminum layer between the positive electrode ear and the aluminum-plastic film; 2. The voltage of the aluminum layer between the negative electrode ear and the aluminum-plastic film.

In theory, the aluminum layer between the positive electrode and the aluminum-plastic film is insulated, which means that their voltage should be 0

In fact, during the processing of aluminum-plastic film, the inner PP layer will be locally damaged, resulting in local conduction (including electronic and ion channels) between them, forming a micro battery and creating a potential difference (voltage).

The voltage standard varies among manufacturers, but most industries set it below 1.0V. The voltage standard is based on the dissolution potential of aluminum lithium alloy!

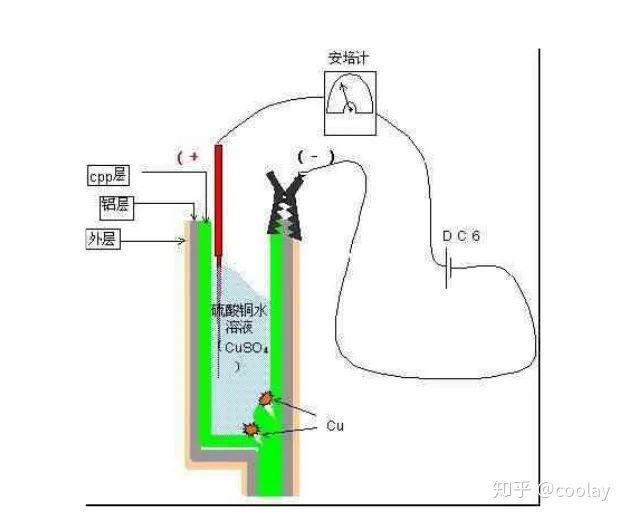

Edge voltage test:

The edge voltage test is mainly used to check the effectiveness of lithium battery packaging film packaging and detect the short circuit between the pole ear and the aluminum foil of the packaging film. Short circuits can cause corrosion of aluminum foil, electrolyte leakage, air bubbles, low voltage, and a series of safety hazards.

The edge voltage of lithium polymer batteries specifically refers to the voltage of the aluminum layer between the positive electrode ear of the soft pack lithium battery and the aluminum-plastic film. In theory, the aluminum layer between the positive electrode and the aluminum-plastic film is insulated, which means that their voltage should be 0. In fact, during the processing of the aluminum-plastic film, the PP layer in the inner layer will be locally damaged, causing local conduction (including electronic and ion channels) between them, forming a micro battery and resulting in a potential difference (voltage). The voltage standard varies among manufacturers, but most industries set it below 1.0V. The voltage standard is based on the dissolution potential of aluminum lithium alloy!

The potential difference between the positive electrode ear and the aluminum-plastic shell is used to check whether there is an electronic channel between the negative electrode ear and the aluminum-plastic film. If there is an electronic channel between the negative electrode ear and the aluminum-plastic film, and the PP layer inside the aluminum-plastic film is damaged, corrosion may occur.

One of the causes of bloating is packaging corrosion:

This bloating is very annoying. Without good detection methods, it is difficult to control defective products within the company and deliver them to customers. After waiting for a few months, it gradually appears, manifested as bloating, leading to returns.

In fact, at this point, the aluminum-plastic film of the battery cell has already been corroded off, and water vapor enters the interior of the battery through the corroded aluminum-plastic film and reacts with the electrolyte to produce bloating.

Why control the edge voltage?

Because if the PP film inside the aluminum-plastic film is damaged, there will be corrosion damage to the capacity.

The conditions for corrosion must have two points: 1. Electronic pathway, formed by the negative electrode and the aluminum layer of the aluminum-plastic film; 2. Ion pathway, the aluminum layer of aluminum-plastic film and electrolyte form an ion pathway; Without any one, corrosion cannot be established.

After both conditions are met, lithium ions will react with the aluminum layer of the aluminum-plastic film to form lithium aluminum alloy; And lithium aluminum alloy is a powdery substance that causes the aluminum-plastic film to penetrate; That is to say, there are some black spots inside the aluminum-plastic film that we often see; These black spots will become more and more obvious over time and with an increase in the number of charges and discharges.

How to choose?

The currently available detection methods include:

1. Testing the resistance between the aluminum-plastic film and the negative electrode ear, if it is greater than 5M ohms, it is relatively safe. Some companies define it as relatively low. Based on the final PPm of the defective product that everyone can tolerate, you can calculate some data and define your own standards; This resistance test mainly involves selecting the electronic pathways;

2. The current between the positive electrode and the aluminum film can be tested using a DC source. Generally, if the current is greater than 0.001mA, it is considered a defective product and needs to be picked out;

3. When testing the voltage between the positive electrode and the aluminum film, it is generally considered a defective product if it is greater than 1V.

Can be tested in combination with 1 and 2, or 1 and 3