Polyolefin giant expands production! Wanma and Wanhua Launch a Battle for the High end Market

On October 9th, Nordic Chemicals announced a major investment to expand its cross-linked polyethylene (XLPE) production capacity at its Stenungsund plant in Sweden.

Including: 1. Building a new medium voltage cross-linked polyethylene (MV XLPE) production plant to produce a new generation of homopolymer XLPE grades; 2. Expand the production capacity of high-end cross-linked polyethylene (HV/EHV XLPE) for high and ultra-high voltage applications; Simultaneously expanding the closed-loop system from individual units to final packaging to ensure high standards of cleanliness for the product.

It is reported that the project is scheduled to be completed in 2026 and put into operation in 2027.

It is worth mentioning that Nordic Chemicals has previously announced, in collaboration with its joint venture company Boru, that its production capacity will double by the end of 2027; The 100000 ton XLPE expansion project located at Ruwaisboro 4 factory in the United Arab Emirates will be put into operation by the end of 2025 to meet the surge demand for high-end cables.

Trillion race track, new blue ocean

In recent years, the interconnection of global power grids, the integration of new energy into the grid, and the construction of offshore wind power have been advancing simultaneously, driving up the global demand for cables. The market size is expected to climb from 1.5 trillion yuan in 2023 to 2 trillion yuan in 2030. As a key material for ensuring the safe operation of cables, the reliability of insulation materials is crucial.

According to the main insulation medium, high-voltage cables are divided into oil filled cables, oil immersed paper cables, and extruded insulated cables. At present, XLPE is commonly used as the main insulation material for high-voltage extruded cables.

XLPE (cross-linked polyethylene) is a thermosetting resin made by crosslinking polyethylene. Its chemical properties are stable, and it has excellent low-temperature resistance and acid alkali resistance. It is a relatively high-quality electrical insulation material, especially in the field of long-distance and large capacity power transmission, with obvious advantages.

At present, the global core manufacturers of this material include Dow, Nordic Chemicals, Zhejiang Wanma Polymer Materials, Avient, and Sissoko.

The Difficulty of 'Locking Throat' in China

The main downstream cable field of XLPE can be divided into low voltage, medium voltage, and high voltage according to voltage.

Among them, high-voltage cables are the main component of this market, and data shows that by 2025, the market share of this segmented market is expected to approach 53%. However, in terms of insulation materials, ultra-high voltage materials in the international market are mainly monopolized by Nordic Chemicals.

In the past decade, in order to achieve the localization of high-end polyethylene materials, domestic enterprises such as Zhejiang Wanma, Qingdao Hanlan, Jiangsu Dewei, and Wanhua Chemical have successively carried out domestic research and development. At present, Wanhua Chemical has relied on the advantages of upstream and downstream integration, utilizing pipeline transportation to achieve integrated supply of base materials and modified materials, and producing XLPE products with ultra-high voltage levels in pilot scale.

Taken at Chinaplas 2024

At present, although domestic insulation materials have achieved certain results, with the increasing planning of high-voltage cable projects in China and the continuous improvement of cable operating voltage levels, higher requirements have been put forward for the comprehensive performance of XLPE insulation materials.

insulation performance

Due to high transmission efficiency, low line loss, and low maintenance costs, high-voltage and ultra-high voltage DC cables have become a current research hotspot. Their demand for XLPE insulation mainly includes lower DC conductivity and superior space charge characteristics. These characteristics will directly determine whether the core risk of cable failure - insulation breakdown - can be avoided.

Specifically, in the field of DC cables, the conductivity and space charge characteristics of XLPE respectively dominate different forms of breakdown risk.

Different breakdown modes are closely related to electric field strength and duration of action

1. Conductivity is mainly associated with the risk of electrical breakdown

Impact mechanism:

The electric field distribution of XLPE cables is different under AC/DC voltage. Under DC electric field, the electric field distribution of the cable insulation layer is no longer determined by the dielectric constant like AC electric field, but depends on the conductivity of the material.

The conductivity will increase exponentially with the increase of load temperature. When the cable operates under DC voltage, the insulation layer will form a temperature gradient from inside to outside and from high to low, which makes the inner resistance with high temperature and high conductivity smaller, while the outer resistance with low temperature and low conductivity larger.

According to circuit principles, voltage will be distributed more in areas with high resistance, leading to "electric field reversal" - the electric field strength on the outer side of the insulation layer is higher than that on the inner side, causing the risk of breakdown.

2. Space charge is mainly associated with the risk of "aging breakdown"

Impact mechanism:

The accumulation of space charges will form a huge local field strength inside the insulation, and this sustained and excessive electrical stress will gradually lead to material degradation, trigger partial discharge, and ultimately cause insulation aging and breakdown after long-term accumulation.

In addition, in actual operation, the above two characteristics are interrelated and mutually reinforcing, and they work together to affect the actual withstand voltage strength and service life of the insulation system.

cleanliness

Regardless of the type of breakdown, achieving full process, closed-loop ultra clean control from base material aggregation to insulation material production is the most fundamental and critical prerequisite. It simultaneously solves the two major problems of conductivity anomaly caused by impurities and space charge accumulation.

At present, the ultra clean route is the most mature, and Nordic Chemicals has achieved mass production of ultra clean XLPE insulation materials through dedicated polymerization equipment and full process clean control. However, breakthroughs are still needed in the synthesis of base materials and impurity detection technology in China.

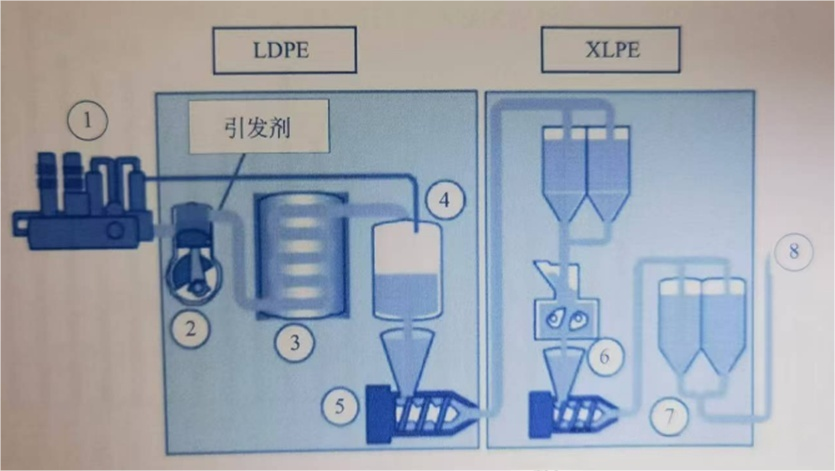

Borlink ™ Polyethylene production process

The impurities in XLPE come from every step of the entire long process, including raw materials, polymerization, transportation, mixing, degassing, and packaging. The purpose of Nordic Chemicals' expansion of its closed-loop production integration system is also to achieve this.

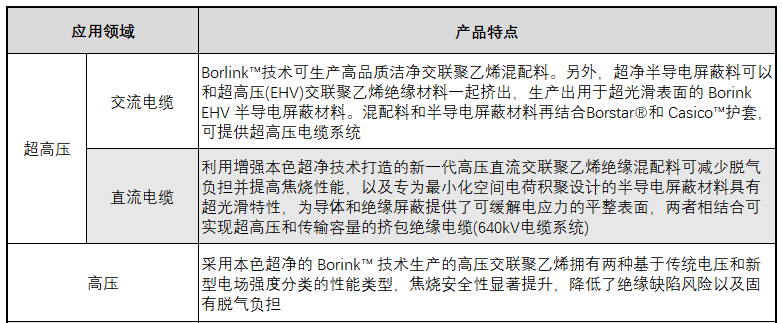

Characteristics of Nordic Chemicals' High/Ultra High Voltage XLPE Products

Stable extrusion process

The extrusion molding of high-voltage XLPE cables is usually achieved by co extruding three layers of melt (inner shielding, insulation, outer shielding) onto a metal conductor, followed by crosslinking reaction to prepare the insulated wire core.

Among them, the control of the insulation material melt extrusion process is a key link in producing high-quality cable products, usually requiring a lower melt temperature to ensure faster start-up speed of the screw extruder and avoid local high temperatures in the flow channel to prevent burning (premature cross-linking, loss of fluidity and reprocessing ability).

In addition, due to limitations in storage, transportation, and other aspects, there is a length limit for the single manufacturing of high-voltage submarine cables, which cannot meet continuous extrusion requirements. Therefore, improving the rheological properties, extrusion stability, and burn resistance of cable insulation materials, as well as optimizing the insulation extrusion molding process, are the key directions for future research and development of ultra-high voltage insulation materials.

In 2018, domestic fiber optic cable giant Hengtong used Nordic Chemicals LS 4201 EHV XLPE insulation material to achieve continuous extrusion of a single 500 kV submarine cable with a length of 18 kilometers, making it the first domestically produced 500 kV submarine cable used in the Zhoushan networking project.

At present, China's wire and cable industry is in a period of rapid expansion. The "West East Power Transmission" and the expansion of the backbone power grid are advancing synchronously with the national networking, resulting in a surge in demand for high-voltage XLPE extruded cables. As the core barrier for the safe operation of the power grid, the technological breakthrough and long-term reliability verification of XLPE insulation material still have a long way to go.

Nordic Chemicals is one of the top ten polyolefin producers globally and a leader in the European market for basic chemicals and plastic recycling.

In 2024, the profitability of its core polyolefin business has significantly improved, and the company has also surpassed others with an astonishing profit growth of 5796.6%, becoming the company with the largest annual profit growth on the Global Chemical Top 50 list